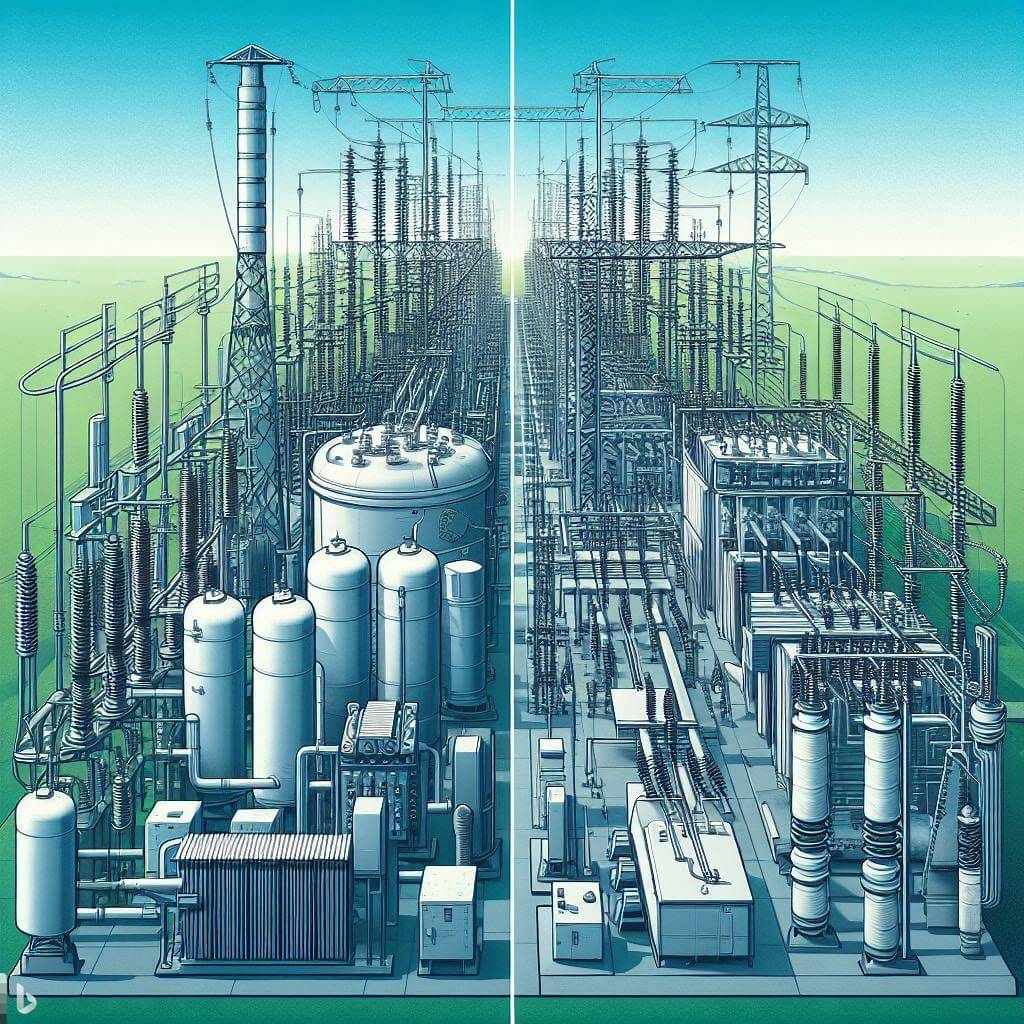

Air Insulated Substation (AIS):

Air insulated substations (AIS) have been in use for many years and remain the primary choice in regions where factors like abundant space, favorable weather conditions, seismic stability, and environmental considerations are not significant constraints. AIS utilizes air as the primary dielectric for phase-to-phase and phase-to-ground insulation. While AIS is a cost-effective solution, its usage is more prevalent in rural areas and sites with favorable offsite terrain. The indoor AIS version, however, is deployed in areas marked by high pollution and saline conditions, where air quality is compromised.

Advantages of Air Insulated Substation:

- AIS is the go-to choice for areas with ample space, making it a practical solution when land availability is not limited.

- The system is cost-effective, with lower construction costs and switchgear expenses.

- It boasts quicker construction times, rendering it suitable for projects that require expedited installations.

- Maintenance is simplified as all equipment is within view, facilitating the detection and prompt resolution of faults.

Disadvantages of Air Insulated Substation:

- AIS demands more space compared to GIS, making it less suitable for projects with spatial constraints.

- It entails more maintenance requirements, resulting in higher long-term operational costs.

- The poor dielectric properties of air, coupled with secondary factors like humidity, pollutants, and moisture, necessitate additional space for effective insulation.

When considering the choice between air insulated switchgear and gas insulated switchgear in the context of substation insulation, it’s crucial to weigh the advantages and disadvantages of each system. The decision is contingent upon project requirements, budget constraints, and environmental concerns. GIS offers undeniable technological and economic advantages over AIS, making it a preferred choice for many substation projects worldwide. Nevertheless, it’s important to acknowledge the global warming issues associated with CFCs and the ongoing debate surrounding SF6, which is why the industry continues to explore more sustainable alternatives.

The last few years have seen tremendous improvement in power generation and distribution. For the power supplier, the most important part is the transmission and distribution control. Due to the large power demand brought about by a growing population and a robust industrial sector, there is a need for the power supply company to embrace efficient methods. One of the key areas is substation insulation.There are two primary substation insulation systems in the world, Gas insulated, and Air insulated substations. The following highlights the primary differences between the two.

GIS Substation

Simply put, in the GIS system, all the live components are enclosed in a grounded metal enclosure, then the whole system housed in a chamber full of gas. Gas insulated substations (GIS) primarily use sulphur hexafluoride gas as the primary insulator. SF6 is non-toxic, maintains atomic and molecular properties even at high voltages, high cooling properties, and superior arc quenching properties. In addition, is safe. SF6 has superior dielectric properties compared to other gases; thereby provide favourable insulation for the phase to phase and phase to ground moderation. In the substation setup, the gas is contained in a grounded metal enclosure containing the conductors, current and voltage transformers, circuit breaker interrupters, switches, and lightning arrestors.

Advantages of GIS

1. The earthed metal enclosure makes for a safe working environment for the attending personnel.

2. Compartmentalized enclosure of the live parts makes for a very reliable system due to reduced disruption of the insulation system.

3. By reducing the distance between active and non active switchgear parts, less space is required than in the normal AIS system.

4. Low maintenance requirements due to expedient design and protection against external elements.

5. Under scheduled maintenance, SF6 neither ages nor depletes. There is no need to top up the gas levels throughout the equipment lifetime (approx 40 years).

6. Quick assembly due to extensive pre-assembly.

Disadvantages of GIS

1. High installation costs compared to AIS systems

2. Procurement and supply of SF6 gas can be a problems especially in rough terrain and off site locations. This further increases the costs

3. High level of maintenance is required. This requires highly skilled personnel

4. Internal faults tend to be very costly and severe when they occur. They often lead to long outage periods.

5. Though the gas is quite inert, flash problems can break it down into harmful by-products such as metal fluoride powders. This poses a health hazard such as physical asphyxiation and other respiratory problems.

AIS Substation

The AIS uses air as the primary dielectric from phase to phase, and phase to ground insulation. They have been in use for years before the introduction of GIS. Actually, most substations across all regions are AIS. They are in extensive use in areas where space, weather conditions, seismic occurrences, and environmental concerns are not an issue such as rural areas, and favourable offsite terrain. The indoor AIS version is only used in highly polluted areas, and saline conditions, as the air quality is compromised.

Advantages of AIS

1. The primary choice for areas with extensive space.

2. With quality design, the system is viable due to the low construction costs and cost of switchgear.

3. Less construction time, thereby more suited for expedited installations.

4. Easy maintenance as all the equipment is within view. It is easy to notice and attend to faults.

Disadvantages of AIS

1. More space is required compared to GIS.

2. More maintenance requirements, thus leading to high costs.

3. The poor dielectric properties of air, as well as secondary factors such as humidity, pollutants, moisture means that more space is required for efficacy.

In the rapidly evolving landscape of power generation and distribution, the key to a reliable and efficient power supply lies in effective transmission and distribution control. With a burgeoning global population and a thriving industrial sector, power supply companies are under increasing pressure to adopt innovative and efficient methods. Substation insulation plays a pivotal role in this endeavor, with two predominant systems at the forefront: Gas Insulated Substations (GIS) and Air Insulated Substations (AIS).

Conclusion

For the engineers and technicians, the choice between GIS and AIS depends on the pros and cons between the two. However, for the many substations projects around the world, GIS offers the obvious choice. This is due to the technological and economic advantages associated with GIS over AIS.Well, the only downside is the global warming issues associated with CFCs. Until the time SF6 is banned, it remains the best option.

Source: Electrical Equipment

3 Responses

Very useful

Thnks to provide the knowledge

This is very confusing regarding overall cost for erection but thanks to reach info.????